Failures of forging dies are caused by very complex wear mechanisms at the surface of the die cavity subjected to severe abrasion, impact and thermal loads[1]. In the case of hot or warm forging, the primary modes of die failure are abrasive wear (60%), mechanical fatigue (20-30%), plastic deformation (10%) and thermal fatigue (5%), see Fig.1[1].

Defining forging die failure — Tool failure often is a combination of more than one failure mechanism, depending on the specific of forging process (open die, impression die or closed die); the forging material (aluminum, steel, titanium or superalloy); the press type (hydraulic, mechanical, screw or hammer); and the selection of forging parameters.

In addition, several types of die steels are used in the forging industry, including low-alloy steels (FX), medium alloy steel (H-13), or high alloy (tungsten or moly-based) steels. Because the damage to the die is primarily limited to the near surface layer (approximately 2 mm deep), surface engineering opens up a variety of possibilities to improve die-service lives[1-3].

Gas- or plasma-assisted nitriding treatment is known for increasing durability of forging dies by a factor of 1.2-6, depending on the stress and the production volume of the hot working dies[2].

Nitrided layers formed in the hot-working steels used for building such tools has increased hot strength and thermal stability. The hardness of the nitrided case exceeds the hardness of quenched and tempered steels by about 350–430 HV30[2].

Surface properties critical for die performance can be further elevated by a surface-treatment process employing a multi-gradient design strategy, a novel plasma, multi-step treatment with formation of the nanostructured layer/coating developed by Advanced Heat Treat Corp.[1, 4]. This new three-step process combining plasma nitriding with the plasma enhanced nanostructures step (PENS) is carried out in a mixture of gases supplying elements needed for enhancing thermal stability of the layer. In this gradient strategy, the low-friction and thin nanostructured surface is supported by a hard compound zone that in turn is supported by a large diffusion zone[1, 4].

This triplex architecture provides for gradual transition of hardness and elasticity gradients from the surface to the substrate, thus reducing the three modes of forging wear: surface abrasion, plastic deformation and mechanical fatigue. The developed gradient coating was shown to possess structural and mechanical attributes beneficial to the service life of forging dies[4].

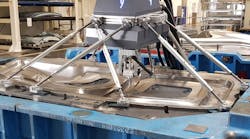

Plasma treatment of forging dies — Plasma nitriding treatment has been known for a number of years as a prime technology for enhancing mechanical and thermal properties of many engineering components, including stamping and forging dies[2]. The process can be observed and controlled by the port window (see Fig. 3.)

Doping of plasma with proper chemicals results in further enhancement of the structure. The active species formed in plasma at the surface of the die penetrate the steel and form a layer with the desired structure, as depicted in Figure 4.

The typical hardness profile achieved in the H-13 hot-work steel is shown in Figure 5[4].

Numerous forging and stamping dies are treated successfully by Advanced Heat Treat Corp. The company has a variety of plasma/ion nitriding equipment sizes and can handle dies as large as 150 in. diameter and 360 in. long, and weighing 60,000 lbs.

Dr.Edward Rolinski is the senior scientist and Mike Woods is the president of Advanced Heat Treat Corp., with locations in Alabama, Iowa, and Michigan. Learn more at www.ahtcorp.com

References

1. R. Shivpuri and E. Rolinski, “Plasma Enhanced Nanostructures for Improved Life of Forging Dies”, unpublished report, 2016.

2. H.J. Spies, A. Dalke. “Case Structure and Properties of Nitrided Steels.” Comprehensive Materials Processing, Krauss, G., Ed.; Elsevier Ltd., 2014; Vol. 12, pp 439–488.

3. E. Rolinski, "Plasma-Assisted Nitriding and Nitrocarburizing of Steel and other Ferrous Alloys,” Chapter 11, Thermochemical Surface Engineering of Steels. Ed. E. J. Mittemeijer and M. A. J. Somers, Woodhead Publishing, 2014, pp 413-449.

4. E. Rolinski, J. Machcinski, J, McCann, and M. Woods. “Silicon Enhancement of the Compound Layer for Tribological Application of Nitrided Hot-Work Steel”, Thermal Processing in Motion 2018 Conference Proceedings, June 5-7, 2018, Spartanburg, S.C., USA. pp.129-136.