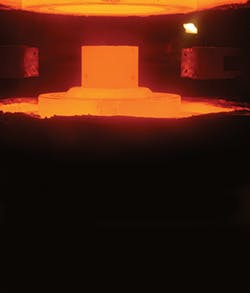

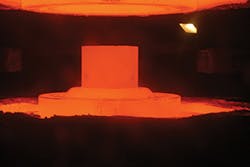

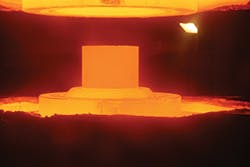

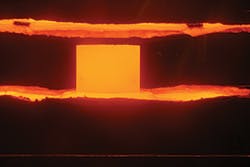

Isothermal forging in action at Ladish Forging, Cudahy, WI.

Ladish Forging, perhaps the world's top producer of forgings by the isothermal process, expects to solidify its standing by adding another isothermal forging press at its plant in Cudahy, WI. the new press will be the third in operation for the Milwaukee-area forger, and rated 25% higher than the larger of the two isothermal presses in place there.

Ladish Co. briefly reported it was investing in the new isothermal press in March 2006. Now, Erie Press Systems president Doug Currie, explains that production of Ladish's new isothermal press is underway at his company's plant in Erie, PA. He states that it will be the world's largest isothermal forging press, rated at 12,500 tons, and it will allow Ladish to forge larger-diameter, close-tolerance forgings now needed for high efficiency jet engines.

Erie Press Systems manufactures custom hydraulic and mechanical presses and machinery for a broad range of metal and non-metal forming processes. It has supplied equipment for open and closed-die forging since 1895.

The new isothermal press will increase Ladish's operational flexibility and capacity, giving the company significant production advantages now and in the future. "Our challenge was to produce a strain-rate controlled, high-tonnage press to forge critical aerospace materials," Currie said. The details he provided include:

The press will weigh over 1,200 tons, stand 33 feet above the floor, and extend 27 feet below it; Four massive tie rods, each weighing more than 100,000 lb, will support the structure; Two main rams will drive the crown and rugged press guides will maintain tooling parallelism; Two push-back cylinders will return the press to the open position.

This pull-down design press is being equipped with the latest in hydraulic and electrical/electronic controls and integrated with a vacuum chamber, multi-station furnace, and part-handling system.

"The hydraulic controls are a combination of servo-controlled pumps driven by 100-hp motors," Currie added. "Using energy-efficient servo controls, the maximum input to drive the press will be less than 275 hp. Forging speed will be adjustable for precise, strain-rate-velocity control, while increasing to a maximum force of 12,500 tons. The hydraulic power unit will use manifold-mounted-cartridge valves to minimize space requirements and simplify piping and maintenance. The modular hydraulic system will be preassembled and tested at Erie, to facilitate installation on site."

The design specifies electrical controls for simple operation, and high-level diagnostic capabilities for quick fault detection. Intelligent control is used to view and log all motor-data parameters.

The press I/O is designed into functional groups and connected to remote I/O modules to reduce wiring. Redundant safety circuits are used throughout the electrical design for safety. Ethernet communication provides high-speed data transfers. Power management for control and data acquisition ensures that information is not lost in the event of a brownout or main-power failure.

All operating, maintenance, and vendor manuals, along with hydraulic and electrical schematics, will be available on-line at the main operator console, through the machine PC. Remote diagnostics and trouble-shooting capabilities will be available through an Ethernet or phone connection.

Press-performance data for each part forged will be collected, recorded, and sent to a database for traceability by serial number.

According to Currie, "Given Ladish's production schedule, not only is it imperative that we meet or exceed rigorous quality and performance requirements for design, manufacture, and installation, but equally important, that Erie controls delivery performance of critical-path components through on-going, project-scheduling review, technical liaison, and inter-company communications vital in a project of this magnitude."

Gene Bunge, Ladish's v.p. of engineering, is part of the project team overseeing the design and installation of the new press, scheduled to be making parts in 2008. "We have spent considerable time thinking through the demands that will be placed on this press, and we know we are building a resource that will serve jet-engine manufacturers for decades to come," Bunge said. "We are excited to be working with Erie to create the world's largest press — one that can meet all the component-technology and production demands our customers require."

Ladish operates two isothermal presses at Cudahy, one rated at 10,000 tons (which Ladish officials claim is the world's largest ), and another rated at 4,500 tons. "Ladish has always been at the vanguard of forging technology," Kerry L. Woody, company president and CEO, pointed out at the time of the announcement. "This project marks another milestone for Ladish.

"Since the early 1970s when we built the world's first isothermal press, we have pioneered the development of the isothermal process, working hand in hand with jet engine manufacturers and raw material suppliers."

He added, "The new unit will be larger and more productive than our existing equipment and will allow us to improve service to customers. Locating the new press next to our other two isothermal resources allows us to take full advantage of the engineering and operational expertise of our Wisconsin workforce."

"Airbus and Boeing are demanding engine makers such as GE and Rolls-Royce provide commercial engines with significantly improved fuel efficiency and fewer emissions," noted Gary Vroman, Ladish v.p. of sales and marketing. "Engine manufacturers can only achieve this goal by using superalloy materials, and these materials must be forged on an isothermal press. Market demand is now at an all-time high — and it's projected to go even higher as the world's airlines upgrade their fleets. We have an 18-24 month projected installation timeline to support a market showing every sign of sustainable growth. There is simply no company better equipped than Ladish to respond to this materials-technology requirement."

In 2001, Ladish directors approved a comprehensive fouryear, $75-million capital investment plan for the Cudahy, WI forging operation. At the time, Woody explained that "Nearly every airframe and jet engine manufacturer worldwide uses Ladish forgings in their products."

Ladish Forging activity in the area of technology includes the development of a Super Cooler, a proprietary high-velocity quenching process for rotating jet engine parts, for which a patent is pending. New equipment includes an aluminum heat-treatment facility, featuring process controls designed to meet stringent aerospace requirements for temperature uniformity and quench-transfer times.

"Our customers demand better solutions, our shareholders expect improved value in their investment, and our employees are committed to continuous improvement," Woody states. "This modernization plan will benefit all stakeholders, and ensure our future as a preferred supplier to the world's finest aerospace industries."

|

Understanding isothermal forging FIA continues: "Heat transfer from the workpiece to the die surfaces causes thermal gradients in the workpiece. The cooler areas at the die surfaces undergo less plastic flow than in the hotter core areas, so that plastic flow is not uniform. This is termed ‘die chilling.' In conventional forging practice, dies for steel forgings typically are heated to a maximum temperature range of 400°-500°F (205°- 260°C), depending on equipment, to reduce chilling. The effects of chilling can be reduced by using fast-acting forging machines, too, such as hammers, screw presses, and mechanical presses, to reduce the contact time. The use of glass lubricants assists by forming a thermal barrier between the workpiece and die surfaces and reducing the die chilling effect. "Die chilling can be reduced by heating the dies nearer to the actual forging temperature. Die chilling can be eliminated entirely by heating the dies to essentially the same temperature as the workpiece. The former is called hot die forging; the latter isothermal forging. "Aluminum alloys are usually hydraulic press-forged under isothermal or near isothermal conditions at around 800°F (425°C). In this range, conventional die materials do not undergo any significant loss of strength or hardness. "However, steels and alloys of titanium and nickel are forged in the range of 1,700° to 2,300°F (925 to 1,260°C.) Isothermal forging of these alloys requires special tooling materials, such as nickelbased superalloys and molybdenum alloys for dies, and lubricants that can perform adequately at these temperatures. Special attention to the surrounding atmosphere is also important, such as the use of an inert gas or vacuum to protect both the dies and the workpiece from oxidation. "Hot die and isothermal forging offer advantages and disadvantages. The primary advantages are closer forging tolerances resulting in reduced machining and material costs, a reduction in the number of preforming and blocking operations resulting in reduced processing and tooling costs, and the use of slow ram speeds resulting in lower forging pressures and the use of smaller machines. "The primary disadvantages are the requirements for more expensive die materials, uniform and controllable die heating systems, and an inert atmosphere or vacuum around the dies and workpiece to avoid oxidation of the dies. The typical production rates are very low to permit proper die filling at the low forging pressures." |