You know a landmark when you see one. Think, for example, of the Statue of Liberty. There is nothing else like it. It dominates its surroundings, and defines the activity around it. That sort of a landmark also fires the imaginations of the people in its presence. It fills them with pride, with a sense of who they are and of their purpose.

In both these ways Alcoa has such a landmark with its 50,000-ton forging press in Cleveland. The 12-stories-tall machine embodies the history of that operation, and now that it’s been rebuilt after a three-year, $100-million redesign program, the “50” is emblematic of the ingenuity of the designers, technicians, and operators Alcoa believes distinguish it as a manufacturer of critical parts.

“Our iconic press played an integral role in Alcoa’s rich history and will be an equally key component to our company’s future growth and success,” declared Alcoa Forgings and Extrusions president Eric V. Roegner at an inaugural event recently. “It is vital not only to our business, customers, and employees, but to the continued growth and stability of our manufacturing operations.”

The story of the press would be legendary even if it were not factual. Details recorded by the American Society of Mechanical Engineers, which designated the 50 as a National Historic Mechanical Engineering Landmark over 30 years ago, recall that a need for critical forging capability was deduced during World War II by Allied intelligence officers examining the impressive but lightweight monolithic structures found in downed German aircraft. After the war, the presses that produced those components were revealed, but the largest German press – a 30,000-ton machine — was seized by Soviet forces. That spurred the institution of the Defense Production Act and the establishment of U.S. Defense Dept.’s Heavy Press Program. With federal sponsorship, the Heavy Press Program built four machines in order to produce the components needed for an adequate air-defense program through the Cold War period. Two of those presses — the 50 and its companion, the 35,000-ton press, comprising “Air Force Plant 47” — were installed at the Cleveland Works, with Alcoa as the prime contractor.

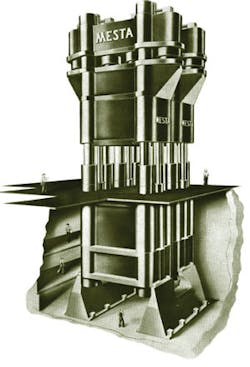

The 50 was built by Mesta Machine Co. in West Homestead, PA, and inaugurated in May 1955. Twenty-four massive steel castings framed a structure 87 feet from the base to the peak, with two “stools” carrying two lower base sections and two upper base sections. The 1226-ft movable die table holding the lower forging die was attached to the base sections. The maximum press stroke was six feet. Hydro-pneumatics (water and a small volume of soluble oil) were used to generate 4,500 psi of pressure from eight cylinders, to generate the 50,000 tons of force that gave the press its name.

Eight forged steel columns framed the structure, which Roegner recently credited as a remarkable example of mechanical engineering “before the entire science of fracture mechanics even existed, before finite element analysis, and particularly before the very advanced statistical sampling and modeling tools available now.

“Using their slide rules and tables they figured out what they thought would be the ‘life’ of the press,” he explained, adding that they were impressively close to identifying the failure limits of the original press.

Of course, it was a failure that set the current story in progress. In the third quarter of 2008, a series of cracks was discovered in the base castings of the press. This was not a complete surprise — Roegner reported that a crack had been found in one of the columns the 1970s, and the press had been disassembled and rebuilt with new columns in keeping with then-current structural engineering — but given the financial chaos of late 2008, and particularly the decline in aluminum prices, it presented Alcoa with what might have been an existential crisis. Not repairing the 50 was never a consideration, to the great relief of many defense and commercial aerospace customers, but something had to be done to restore this landmark piece of production equipment.

Roegner outlined the choices that Alcoa faced: “There were options we considered,” he began. “Patch it together: there are things you can do with a casting to drill, weld, stitch, reinforce, bracket, all that stuff,” he began.

“Start over, and build something completely from scratch,” he continued, “or, leverage everything we have here, but redesign and enhance what we have.”

Economics + Expertise

Two factors informed the decision to take the last option, he said: 1) the economics of that plan were most favorable; and 2) the wealth of expertise among the Alcoa engineers and operators presented what Roegner called “a true differentiator” in the manufacturer’s plan to project all of its technical and manufacturing capabilities, to identify commercial opportunities and solve customers’ problems.

The decision to rebuild must have been a relief to customers like Boeing, Lockheed Martin, Airbus, and others, who have the assurance that the rebuilt 50 will be available for decades to come. “Not only can it do things that no other forge can do, but if you’re making a decision for an aircraft program, you’re pretty sure that this is going to be running for another 30, 40, or 50 years,” Roegner observed. “I would argue that, with very few exceptions around the world, this is not only going to be one the most functional but also one of the most dependable forges – which is important to our customers.”

Deciding to rebuild the 50 was only the first step. By mid 2009, Alcoa had begun making plans to reassign production programs to the ‘35.’ It also conducted an engineering analysis to confirm that the smaller press would be able to maintain an enhanced-duty cycle for two years or more. Having confirmed that, and with no unmanageable obstacles and the financial backing of Alcoa’s board of directors, the rebuild program for the 50 was underway at the start of 2010.

The $100-million project involved more than the 50, naturally. The ancillary equipment and systems, including furnaces and manipulators, had to be updated and optimized to work with the new operation.

Samiron Mondal, sales director for the Metal Forming unit of German press-builder Siempelkamp Maschinen- und Anlagenbau GmbH, explained that a particular challenge of the rebuild project was to work with the existing foundation and to re-use the columns and cylinders. “This meant, for Siempelkamp, that all the parts had to fit in the existing press ‘at first go’,” he recalled. But, aside from those factors, the new machine had to comply with the most advanced engineering standards and maintain what he called “a fatigue-endurable design.”

Mondal also noted that another design condition was that the weight of new press’s individual castings could not exceed 250 tons, due to the maximum carrying limit of the shop crane.

The resulting design is just over 86 ft tall (26.3 meters), of which nearly 37 feet (11 m) are below grade, while the rest rises over 50 ft (26.3 m) above the floor.

The new press has a die size of 10.526.3 (3.28 m), the Siempelkamp exec noted. The pressing force, naturally, is 50,000 tons (450 MN), and the hydraulic system operates at up 320 bar. In addition to various aluminum alloys, Alcoa is able to process Inconel, titanium, and steel alloys.Siempelkamp earned plaudits from Roegner for its partnership role. “We looked around, we went through the process,” he acknowledged. But, “Siempelkamp not only is the best at the ‘net’ set of things that need to be done — from the redesign through to the production of the parts, in a very high-quality way, through the logistics, and the assembly, and the support — but, because we’ve had such a good and trust-based, long-term relationship with them, and they know us, and we know them — it was an easy choice to continue to work with Siempelkamp.”

For example, the German company’s expertise at casting ductile iron made it possible for Alcoa to choose that more demanding, but more structurally reliable material (less prone to porosity and microcracking) to form the 14 mammoth castings framing the new press.

The selection of ductile iron over steel was made rather quickly, according to Siempelkamp’s Mondal. “Alcoa had been operating 18 other presses (built) in ductile iron and never had a problem with them,” he offered. “Ductile iron provide, among advantages, very good absorbing characteristics.”

The size of the ductile iron castings needed for the 50 may have presented some challenge, however. “Siempelkamp said nothing was too challenging for them. In fact, they poured the largest structural iron casting that’s ever been poured, for this project,” the Alcoa executive recalled.

Mondal confirmed that Siempelkamp has expertise in the design and production of ductile iron components, so it was fully capable of developing parts that “are optimized in weight, nearly non-cutting, fatigue-endurable, and adapted to load-induced stress.”

Sampling proved the integrity of the new castings. “We didn’t have a single one of the castings fail,” Roegner noted. “In fact, they all were well within the tolerances that we wanted.”

The choice of hydraulics for the new press involved another strategic partner, Hauhinco Maschinenfabrik. Water-based hydraulics are capable of achieving both very fast and very slow movement, which is critical for a press that is expected to maintain very long strokes. Roegner further explained that because the original machine operated on water-based hydraulics, and specifically because all the existing pumps and accumulators were developed for hydro-hydraulics, that technology was chosen again over oil-based hydraulics to power the new 50.

“The key, then, is to have a control system that can work with water-based hydraulics,” Roegner said, adding that Hauhinco met that challenge with what he said is the largest such system it had ever design, “perfectly integrated with this press. “It’s really about precision: that is, how much tonnage (pressure) can you hold at a point in the press, for how long, and how tightly can you hold the tolerance on that to very precise dimensions?”

The answers to those questions are beyond specification, he said, “because how we control that pressure across that whole surface is one of our truly unique advantages.” He boasted, however, that the press hydraulics were designed to excel at forging large structures with widely varying dimensions. “Most forgers hate doing stuff like that. We love doing stuff like that, … I’ll just say that we designed this control system with Hauhinco to do that very, very well.”

Challenging Dimensions

Producing parts with challenging dimensions is only possible with advanced design engineering and process control capability, and the rebuilt 50 has both of those. “We have, I would argue, pushed state-of-the-art on all of the modeling we do, and the die design and metal flow,” according to Roegner. That capability supports an automation process management system that he called the most advanced of any forging operation at Alcoa.

“We have real-time visual management of every single valve, every single line in that press. And we can control them all. We can see them all, control them all,” he continued. That means Alcoa is able to generate “a digital fingerprint of every single forging,” and volumes of product and process detail on every step of the forging sequence.

Small details are hard to appreciate as one stands in the shadow of a 12-story landmark. But, Alcoa’s customers understand and welcome the opportunities that the rebuilt press creates for them. It’s capable of open- or closed-die forging of large-scale parts in aluminum, titanium, nickel, and steel alloys, which entitles them to consider structural designs for aircraft and other vehicles, power-system parts, and industrial components that were never imagined because they could not be produced. Until now.

“Where we see the biggest opportunity is, hands-down, bar-none, pushing the envelope in aero structures,” Roegner said. He pointed to the inner rear spar of the Airbus A380, “the largest aluminum monolithic forging on earth,” produced by Alcoa and allowing the aircraft builder to achieve high strength for its structure, low-density in the component, and cost savings.

“We can do things that that would have required plate and extrusions and fastened structures, that we can make ‘monolithic’. Now, I would argue that’s just the beginning of where we’re going to go with monolithic structures for both commercial aerospace and defense,” Roegner predicted.

Alcoa and its partners have re-engineered a landmark, and made a bit of history in the process by completing such a consequential project. It stands there as proof of their accomplishment. At the same time, if these design expectations are on target, then the story of Alcoa’s new 50,000-ton press is just beginning.