Have you ever left something behind and remembered it just a millisecond too late to save yourself from disaster? A maintenance tool left behind in a die is every forging press operator’s nightmare. When the machine starts up, damage to both the die and the part being formed, perhaps even to the machine, is inevitable. And that brief moment of forgetfulness may have consequences for the entire system.

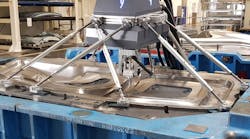

Schuler Group is addressing this potential problem with a new development called Visual Die Protection: it’s a camera-assisted monitoring system that can avoid the prospect of costly die repairs, downtime, and even complete production stoppages.

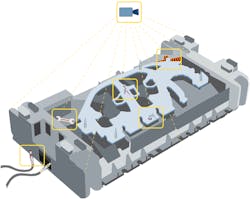

Visual die protection cameras detect the presence of foreign bodies in the die, such as tools or punch scraps: The system also checks whether the die is properly connected and verifies that the blanks have been correctly inserted, formed and removed. More than this, the system is equally able to recognize both cracks in the die itself and potential damage to the centering and ejector pins. If any abnormalities are found, the forging press is stopped to prevent the situation from getting worse.

Schuler will provide customer support for initial system configuration upon request. A feasibility analysis using a mobile image-processing system also is possible. By integrating additional cameras, the system also can be expanded to monitor the scrap chutes and other areas of the machine.