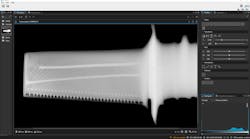

An ADCOLE CORP. gauge provides submicron accuracy with fast, unattended cycle times, for manufacturing and quality control of critical rotating components. The Model 1100 gauge is a complete system that uses dual-linear gratings for measuring 3,600 data points per revolution of cylindrical parts with submicron accuracy. Easy to load/unload and operate, measured parameters for crankshafts include diameter, roundness, cylindricity, straightness, parallelism, taper, radial runout, concentricity, axial runout, index angle, throw, true position, lobing, center deviation, lengths and widths.

Well suited to help engine and driveline component manufacturers maintain the close tolerances required for optimal fuel economy and engine life, the Adcole Model 1100 gauge measures main and rod journals with ±0.5 micron radial accuracy, 0.5 micron linear scan accuracy, ±0.001 degree angular accuracy, ±5 micron axial accuracy, and 10% of tolerance repeatability. It has dual PC CPUs linked via DCOM, Windows 7-based software, and a 19-in. color touch screen monitor.

Visit www.adcole.com