Now, a newly developed two-component ring nozzle for a pulsating jet now allows further cost savings and technical advantages to be realized in CO2 cleaning operations.

The cleaning medium used is liquid, non-corrosive carbon dioxide, which has an unlimited shelf life. It’s an environmentally neutral by-product of chemical manufacturing and biogas energy generation.

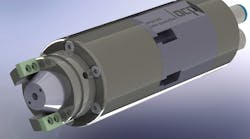

The core of the cleaning system is a wear-free, two-component ring nozzle through which the non-flammable and non-toxic carbon dioxide is fed. On exiting the nozzle, the carbon dioxide expands to form fine CO2 snow, which is bundled by a separate, jacketed jet of compressed air and accelerated to supersonic speed.

When the easily focused jet of snow and compressed air impacts on the surface to be cleaned, a combination of thermal, mechanical, sublimation and solvent effects occur. The interaction of these four mechanisms of action reliably removes particulate and filmic contamination. The aerodynamic force of the compressed air carries away the detached contamination, which is removed by an integrated extraction system. Since CO2 sublimates instantly under atmospheric pressure, the parts are dry at the end of the cleaning step and immediately ready for further processing or packaging.

To increase cleaning efficiency even more and broaden the range of applications, acp systems has further developed its nozzle technology to generate a pulsating jet with a frequency of 25 to 30 Hertz. The pulsating jet of snow and compressed air has a higher kinetic energy than a continuous jet, hence the optimized cleaning effect.

First, the effect of the micro jets (mechanical method of action) is multiplied. This is due to the impulse transmitted when the fine snow crystals impact at high speed on the surface to be cleaned or deburred. Second, each time the pulsating jet strikes the material, an approximately 600-fold increase in volume takes place during the transition from the solid to the gaseous phase (sublimation effect). This causes repeated micro-explosions that enable contaminants to be removed more effectively. Learn more at www.acp-systems.com