Located in Peterborough, England, Marlor Tooling has been designing and manufacturing cutting tools for more than 20 years. The cutting tool manufacturer specializes in delivering innovative solutions for the aerospace, automotive, energy, woodworking, and general subcontract markets.

Discussing the business and the relationship with ANCA, Kevin Taylor from Marlor Tooling says:

“Our business has grown with the technology. We aspire to have the best technology at all times and it has been an absolute pleasure working with the latest ANCA machine, the MX7 Linear. The quality of grind has always been there with the ANCA products, but this particular machine with the RFID technology has taken the loading of the machine to a different level. It’s an absolutely fabulous idea, chaotic loading is what it’s called and we have maximized its use of that. Things that we would consider being unable to load prior to the arrival of this machine, we now load. Whether it is a 1-off, 2-off, 3-off or a mixture of tools, it doesn’t mean anything to us now—everything can be automated. We are now trying to count our lead times in days and not weeks.”

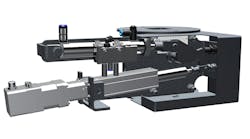

The ANCA MX7 Linear is a powerful, versatile CNC tool grinder designed for production grinding. It is built to meet the demands of high output, high precision manufacturing. The powerful 38 kW (51 hp) permanent magnet spindle provides high torque at lower RPM which is ideal for carbide grinding and a wide range of other applications.

The MX7 Linear is a hard-working, high-productivity system with unique features that enable it to handle varied batch sizes with minimum set-up time. The cylindrical linear motor design increases reliability further and ensures a superior surface finish.

Commenting on the latest installation of the MX7 Linear with RoboMate loader which includes a FANUC LR Mate 200iD robot, Adrian Wright from ANCA says:

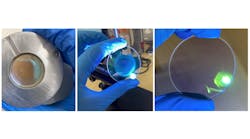

“Marlor Tooling came to us after the FX7 machine was installed. They wanted a good all-around solution for chaotic regrinding, this means they can load tools from 3 up to 16 millimeters in diameter and it doesn’t matter what the tool type is. We can also do small-batch manufacturing as well, once again it does not matter what the size of the diameter of the tool is for the loading sequence, as long as it is within the 3 to 16-millimeter diameter range. The robot is programmed, and the program is done prior to the tools being loaded into the pallet. Then the machine does the rest—it changes the collets and it can measure in process with the LaserPlus System.”

The LaserPlus system provides an accurate and repeatable measurement of tools inside the machine. The LaserPlus can automatically measure OD, run-out, EOT, ball nose, and corner radius profile tools. Typically, the LaserPlus can achieve +/- 3 microns accuracy or better. An air blast unit ensures that coolant or contaminants are cleaned from the tool to ensure nothing hinders the measurement process.

The MX Linear range uses ANCA LinX Linear Motors for axis motion (X & Y axes). In conjunction with linear scales, a high level of machine precision and performance can be achieved, resulting in superior tool accuracy and surface finish.

With LinX Linear Motors there is no loss of machine accuracy over time due to wear and it is not affected by temperature variations. The LinX Linear Motor has a higher axis speed and acceleration leading to reduced cycle times. It achieves this while maintaining a smoother axis motion.

With two pallets in the machine, the ANCA MX 7 Linear can accommodate up to 200 tools.

Referring to this, Adrian says: “it really doesn’t matter if the customer comes to Marlor today and requires five tools to be reground and turned around by tomorrow, the operator can change the five tools at the front of the pallet, or move them to the back of the pallet, if necessary, to ensure a fast turnaround of tools and the machine just carries on.”

“To go from a three-week lead time down to a 24-hour lead time is music to any business owner’s ears. We have the ultimate flexibility here. When you combine this system with the LaserPlus or LaserUlta that can measure the tools in-process, you can intermingle the tools. So, it doesn’t matter if it is a re-grind tool or a newly manufactured tool, we can slot in any tooling and it is the solution for everything.”

Commenting upon the reliability of the ANCA automation system, Kevin Taylor continues:

“It has been great, the system is very solid. We also do our programming offline, and that has its advantages too. We don’t have to stop the machine to do our programming, as the machine is automatically loading the next tool constantly. It’s not a machine you would have traditionally been running manually through the day and loading for automation overnight—it makes no sense. It is loaded all day and all night. The machine does not stop at all, whereas some of our other machines are restricted in size, diameter, and tool types—this machine does not have those restrictions.”