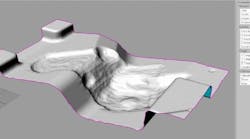

TRANSVALOR released the NxT 3.1 version of its Forge@ software program for simulating hot and cold forming processes, recommended for forging operations supplying parts to various industrial markets, including aerospace, automotive, and medical/surgical products. According to the developer, the first update since the release of NxT 3.0 in spring 2019 includes several new functions and improvements to existing functions, plus a "better ergonomics" that will enhance the user's experience.

First, the developer described a more efficient and intuitive graphical user interface, with new functionalities to accelerate routine tasks, and designed to make "work easier and more comfortable, bringing you a better and personalized experienced." It listed a newly integrated contextual menu, accessible by "right-clicking", that offers quicker access to functions available in the interface and to object parameters. Also, menu customization is possible, for increased productivity.

Other GUI updates include integrated "drag and drop" to simplify file imports; several keyboard shortcuts; new automatic recording options; customized "mouse actions" for simple navigation; options for setting up favorites among simulation models and database elements, for more personalized search/select; improved loading time; and corrections to user-reported malfunctions that may have led to instability, resulting in a more fluid and stable interface.

New features for data setup and results analysis include manipulation on multiple objects at once (rotation, cutting, shifting etc.); simplified visualization and definition of mesh boxes; improved of the mesh parameters, with new options and verification tools; integrated custom actions applicable with a single click (scalar, scale, filter, cutting plane ...); more options for users to customize the interface; synchronized animation; and reduced generation time.

New business-related functions include consideration of phosphate coating of parts, to facilitate forming; incorporation of Quaker-Houghton quenchants in the simulation database; new simulation templates for flow-forming/spinning and aluminum heat-treatment processes; improved computation times for induction and flow-forming processes.

Learn more at www.transvalor.com/en/forge