Twenty years ago, Ted Wilcox was in the U.S. Navy running a repair welding facility that was servicing nuclear submarines. After joining the Navy at age 17, he took all the welding training offered and found he had an aptitude for critical-quality welding. When he was made supervisor of the nuclear welding repair facility, he was the youngest at that time to assume such a responsible position.

Today, he heads up Absolute Welding Inc., which he founded in 1994. AWI is a dedicated forging die welding facility, located in Greenville in southern Indiana, some 20 miles from Louisville, KY. This facility serves forge shops throughout the Midwest and East Coast. At the time of Forging’s interview with him, Wilcox was preparing to open a satellite operation in Ft. Worth, TX.

According to Wilcox, welding offers unequaled ability to extend forging die life. A die with flood-welded working surfaces can have specific alloys placed in specific locations to minimize problems such as wear and die cracking.

A welded die lasts longer than a non-welded die before it must be re-machined; in fact, with flood welding, the overall service life of a die block can be dramatically extended.

With high production jobs, there are fewer interruptions for retooling to produce the same number of forged parts. That means the forging equipment can be more productive, resulting in a more profitable forging operation.

There are less obvious advantages, as well. Welded die blocks can be maintained at the original die height without the shimming required after re-sinking a non-welded die. And hammer dies are maintained at their original weights and heights.

Also, high-value forging components such as bolster plates, hard plates, rams, and sow blocks can be weld-repaired for a fraction of the cost of producing new components and with drastically shorter lead times.

The ability to reclaim obsolete die blocks with die welding is another advantage. An obsolete die block can have the old impression removed and flood welded, making it ready for the sinking of a new impression.

The Welding Processes

AWI uses the four main welding processes:

- GMAW: Gas Metal Arc Welding (MIG)

- GWAW: Gas Tungsten Arc Welding (TIG)

- SMAW: Shielded Metal Arc Welding (stick)

- SAW: Submerged Arc Welding (sub-arc)

“We use TIG welding for trim blade repair. The trimmers wear very rapidly. We usually TIG-weld a Stellite surface onto the cutting edge of the trimmers. That’s our biggest use for TIG. But we also use it for detailed partial repairs, where we go in and precisely fix the part of a die impression where it’s wearing. We use TIG because it gives you total control of heat and how much weld metal you’re applying,” Wilcox explains.

The stick process is used mainly for repairs in very deep impressions or cavities, “where our guns will not reach,” says Wilcox.

The majority of welding at AWI is done with the MIG process.

“We use three sizes of MIG wire: 1/16-inch diameter for overlaying projects, 3/32-inch diameter for depositing the first alloy in the bottom of an impression, and 1/8-inch diameter wire for capping impressions or where large amounts of the weld are required.”

Before a die can be flood-welded, its surface must be prepared.

“When we prep a die for welding,” Wilcox explains, “we cut out the surface of the entire impression and all visible defects. We also shape the impression for the welding process. We do not want walls straight up and down, or especially leaning inward.”

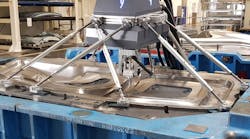

“We’ll put our first alloy or bottom alloy down using handguns; then we’ll move the die over to a welding manipulator station to finish the job using a remote-controlled gun with 1/8-inch welding wire. This gives us the ability to apply the weld deposit much faster.”

Wilcox outlines the details: “Manipulator welding involves using a water-cooled gun or torch where the operator sits a couple of feet away from the heat. The gun operates at 750 amps with 1/8-inch wire. Trying to do that with a handgun, working right over the welded area, would be very difficult for the operator.

Addressing Multiple Problems

“Alloy selection is very important in solving a customer’s problem. Two major problems can be dealt with through alloy selection, they are flash-land and forming-radius wear. Another is cracking in the bottom of an impression. The tighter the radius at the bottom, or the deeper the impression, the more potential there is for cracking.”

Because success with die welding depends on weld alloy selection, most customers leave the alloy selection up to AWI.

“For many alloys,” Wilcox says, “the manufacturer gives the as-welded hardness, so when we quote a job and describe each alloy we use, we give the as-welded Rockwell hardness, but we also quote for the customer what the hardness will be after our heat-treating process.

“With die welding,” Wilcox explains, “we can address multiple problems. We normally use two alloys, but we can use three or even four alloys, especially in deep cavities. This process is called composite welding.”

Temperature control

The other important factor in dealing with die problems is controlling the temperature of the die block before, during, and after welding.

Before welding, the die block is slowly heated in an electric furnace to a specific temperature, typically a minimum of 800ºF. The die is held in an electric furnace during welding (unique to AWI), with only the weld area exposed for access. This approach maintains the die block at the 800ºF temperature throughout the welding process.

Wilcox continues, “After a die block has been welded, the weld deposit area is hotter than the rest of that die block, so we return the dies to the preheat furnace after welding to allow its temperature to equalize. We allow the temperature of the die block and weld deposit to equalize at a uniform temperature of 800º or above.

“Once it’s equalized and all one temperature, we then move the die to our controlled-cooling area where we can control the rate of cooling. We slow-cool it to the required temperature prior to stress-relieving. We monitor exactly how far a die cools down before stress relieving because some of the alloys have different stress relief requirements.

“The reheat for stress relieving is based on a 50º increase per hour. The die block comes up to its stress relief temperature, it’s then held at that temperature for 1 hour per inch of thickness. That’s what’s required for the heat to soak uniformly through to the center of the die block.

The normal turnaround time for preheating, welding, equalizing, controlled cooling, and stress relieving is 7 to 14 days. To maintain this turnaround time, AWI welds two shifts a day, six days a week. Heat treatment goes on seven days a week.

AWI does provide die-welding services on an “emergency” basis, but the term is relative, according to Wilcox, because the heating and cooling times required with die blocks can’t be shortened.

“A die that weighs 10,000 pounds will take over 24 hours just to preheat it. Then, the preparation and welding can take days, depending on what is required. Finally, the die must be equalized and stress-relieved. All that takes a long time, so two weeks is a fast turnaround for big dies.”

Welding Virgin Dies

Wilcox finds that customers who need replacement dies, and who know what welding can do for them in extending die life, do not want to run virgin blocks. “The customer does the external machining on the new die block without sinking the impression.

“The blocks are sent to us with the blueprints, we layout the impression for the die block, and then we scarf (cut) it out with the arc carbon process, which is much quicker than by rough machining. Usually, we can do in a half an hour what it would take a half-day to do by machining. We know how deep the weld deposits need to be and where each alloy needs to be, so we cut to the required depth and then deposit our weld. With this approach, the customer gets maximum die life when the die goes into production.

“The only time we feel that you should not weld is a first-time job. The customer wants to run prototype parts, and make any necessary engineering changes to the die. And we want the customer to see what die life he would get without die welding. He’s then established a benchmark for us to exceed.”

Most die blocks handled by Absolute Welding fall in the range of 400 to 4,000 pounds. “The largest part we worked on recently,” Wilcox recalls, “was an 18,000-pound bolster plate. The smallest, which we have in-house right now, is a press die that weighs 25 pounds.”

Heating and Cooling

“We have a size limit on what we can put into our standard furnaces, Wilcox says. “We have preheat furnaces that are 10 feet long, but our stress relief furnaces only go up to 6 feet long. To process the bigger products, we use a platform with electric heating pads. We can put a die on this platform and cover it with insulation regardless of how big it is.”

The electric welding furnaces at AWI are built so die blocks fit inside them. Only the weld area is exposed for access by the welder. The furnaces have carbon steel walls and are lined with 6 inches of fiber insulation and a layer of stainless steel mesh.

Die temperatures are monitored with thermocouples and maintained at the preheat temperature throughout welding. Two large controllers are available to control up to six furnaces each.

Paying close attention to heating and cooling the die blocks is very important, according to Wilcox.

Preheating increases ductility in the base metal, reduces thermal shock to the base metal from arc welding temperatures, and retards the solidification rate of weld metal. These measures all reduce the possibility of die cracking.

Post heating equalizes the temperature of the weld metal and base metal. This is important because they shrink as they cool down, and if they shrink at the same rate, it reduces the formation of stresses that can lead to cracking.

Tempering removes welding stresses, induces toughness into the heat-affected zone, and induces toughness into the weld metal, without necessarily reducing hardness.

A step in die welding that isn’t discussed very often, according to Wilcox, is peening. Immediately after weld metal is deposited, and while it is cooling it is peened with a tool similar to a mini jackhammer. The peening process counteracts the tendency of the weld metal to shrink and tear away from the die metal. The peening device is mounted on a tool balancer so the operator has to apply very little pressure to peen, making it easier to thoroughly peen a weld deposit.

A growing number of customers are doing their own re-sinking. Currently, about 70 to 75% do the re-sinking in-house. Wilcox looks for that percentage to pick up due to the new high-speed CNC milling centers that are available. A forge shop can have one trained operator running up to three high-speed milling units. Another advantage of the high-speed mills is they can cut the hard capping alloys that at one time had to be finished with the EDM process.

“We will work with independent diesinkers who handle the re-sinking for forgers,” Wilcox says. “We also will take responsibility for securing the machining, serving as a tier-one supplier able to give the customer an overall price for welding and machining a die.”

Wilcox got started in welding forging dies by taking over the flood-welding shop of a forging company that all but had given up on the process. Within weeks, he turned the operation around. Later, when the company went through a downsizing process, he founded Absolute Welding and began servicing the company’s die-welding needs. That company today is Ted Wilcox’s oldest customer and one the most successful, having been with him for 10 years.

Gradual Growth at AWI

At the beginning of AWI, Wilcox did all the work himself along with his office manager Barbara Moller.

“Five years ago we reached a point in our growth where we needed to upgrade our capabilities and training process,” he recalls. He hired Scott Ayers to serve as welding supervisor due to his extensive experience and training in die welding techniques.

Later, he hired John Raymer, who had experience with one of the first independent die welding facilities, then with a large forge shop that had an in-house die welding facility. John also served for five years as a consultant and sales representative for the leading manufacturer of welding alloys. Raymer is now plant manager at AWI.

With Wilcox, Raymer, and Ayers, plus other key people, the company has a total of over 70 years of experience in die welding.

AWI serves customers as far away as Texas in spite of the expense of trucking the die blocks to Indiana. Ted Wilcox decided to do something about this situation.

Early in April 2004, he took possession of a 10,000-square foot industrial building in Fort Worth, TX, in order to establish a forging die welding facility in the Southwest. The equipment will be similar to that used in Greenville, and he will hire and train staff as demand dictates.

With this new facility, Wilcox envisions serving the entire Southwest and West Coast, and even northern Mexico.